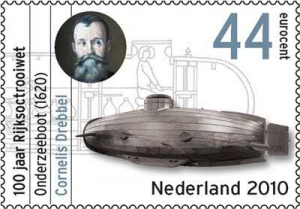

Cornelis Drebbel: the magician of the 17th century

CORNELIS DREBBEL (1572-1633)

Cornelis Drebbel was born in 1572 in Alkmaar (NL), in a well-to-do family of land owners. Drebbel’s education was elementary, only later in life he learned Latin, but Hendrick Goltzius, famous for his engravings but also capable in chemistry, teached him a lot. Drebbel moved in with Goltzius in Haarlem to become his assistent and later he married a younger sister of Goltzius. As early as 1598 Drebbel got a patent for a pump and a clock with perpetual motion.

From 1605 till 1610 he stayed in the Court of King James I in London. Here Drebbel really blosomed as an inventor, in the years 1608 and 1609 he was busy perfecting a magic lantarn and a clavichord. His fame started to spread all over Europe and the next three years Drebbel lived in Bohemia.

Under the wings of ruler Rudolf II in Prague Drebbel focused mainly on his perpetuum mobile, alchemy and the production of gold alloys for the German mint. The period in Prague ended with a lot of turmoil and Drebbel was even thrown into prison.

After his release Drebbel fled to London where he would stay until his death in 1633. Here his main point of focus was building his submarine but, as illustrated by his visit to Middelburg in 1620, he was also interested in optical instruments. In 1621 Constantijn Huygens (1596-1687) visited London and between January 23 and April 30 he had a number of brief meetings with Drebbel. Huygens says the following about these visits:

“I saw Drebbel also for a short time. In appearance he is a Dutch farmer, but his learned talk is reminiscent of the sages of Samos and Sicily. I wished to profit by your company for a longer time, great grey

beard, but the brevity of the time stood in my way, and against my will you are postponed for a another year.”

In the period from 1626 till 1629 Drebbel worked for the British Navy. mainly because of his submarine (the Navy saw opportunities for the vessel in war time) but also because of the water mines he produced. Unfortunately his period with the Navy ended because of conflicting thoughts about the value of his inventions.

Drebbel didn’t end his life as a rich man. The last four years of his life he was a brewer and owner of an inn below London Bridge. He used his invention of staying under water for a significant time to attract people to come to his inn and drink his beer.

An overview of the inventions by Cornelis Drebbel shows the following:

- Perpetuum mobile: a sort of air thermometer that worked with a certain volume of gas that variated with temperature and pressure. This is the most famous invention by Drebbel and it is interesting to see that the apparatus shows up in a whole lot of paintings from that period. In his autobiography from about 1630 Constantijn Huygens (who is of course the father of Christiaan Huygens) writes the following about Drebbel’s perpetuum mobile:

“The perpetuum mobile, which I know only from the drawing of it is so cleverly constructed, that no one, as far as I am aware, has been able to discover the hidden causes at work not even after it was broken. In a glass

spiral is a liquid, which reproduces the ebb and flow of the sea repeatedly (a thing I cannot believe), which certainly is brought about by self initiated motion back and forth and which enthrals experienced persons as much as inexperienced ones by its extraordinary continuance. I suppose it is something of the same sort as that, which now no longer astonishes us, where in a similar glass the enclosed liquid enables us to judge of the temperature of the day by the instability or mobility of the liquid. It is quite certain that the water is forced to rise to fill the empty space, when the air is pressed together by the surrounding cold and that the water is pressed down again and is chased away, as if by the ebbing of the tide, when the air expands by warmth.”

- Ovens and furnaces: Drebbel was very good at building these kind of contraptions. He even built a furnace of which the temperature could be held at the desired level.

- Automatic musical instruments

- Hydraulic inventions: as early as 1598 Drebbel obtained a patent for a construction that was equal to our system of water ducts and which could pump drinking water from different depths according to the need.

- Telescopes and microscopes: It is not for certain but a lot of people see Drebbel as the first person to build a microscope. Drebbel did a lot to spread the word all over Western and Southern Europe and even Galileo knew about his invention. Christiaan Huygens spoke with praise about Drebbel’s microscope. Drebbel was a brilliant glassblower.

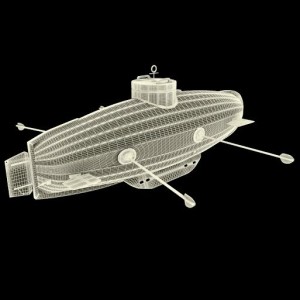

- Submarine and oxygen: In 1620 Drebbel built a submarine for the English King. The vessel contained 24 people, 8 of which were rowers, navigated a couple of miles below the water level in the Thames, could change it’s depth, kept it’s course with a compass and could stay in the water for 24 hours without running out of oxygen. Drebbel had made a thorough study of oxygen and several papers claim that he produced oxygen by heating salpetre.

- Production of explosives

- Colouring of fabrics: Drebbel invented a method to colour fabrics with scarlet red by using a tin salt. This colour already existed but Drebbel’s red was much more powerful and intense.

Cornelis Drebbel and Jaeger-LeCoultre’s Atmos clock

Perpetuum mobile by Cornelis Drebbel, H.M. Hiesserle von Chodau, 1612

Jaeger-LeCoultre Atmos classic

With his invention of the perpetuum mobile Drebbel made the base principle for the Atmos clock manufactured by Jaeger-LeCoultre three centuries later. Through the years more of these objects were fabricated, Leonardo da Vinci also worked on a perpetuum mobile, but it took until the 20th century before the principle could be turned into a working clock.

In 1927 French engineer Jean-Leon Reutter developed the first Atmos clock, which is now called the Atmos 0. His clocks were driven by a “mercury in glass” expansion device which rotated a cylinder which wound the mainspring by ratchet. The mechanism operates on temperature change only. The clocks are slightly different to the later Atmos models in minor details of escapement. A temperature difference of one grade between 15 and 30 grades Celsius is enough to keep the clock running for 48 hours. To be able to turn these very small amounts of energy into movement the Atmos clock has completely different numbers than a regulair pendulum clock. The balance only makes two torsional oscillations per minute, 150 times slower than the pendulum of a standard clock. To put the amount of energy that an Atmos clock uses further into perspective the following comparison: 60 million Atmos clocks together don’t use more energy than a light bulb of 15 Watt.

In the history of the Atmos clock two things catch our attention. On June 1 1929 the Compagnie generale de radio (CGR) created a department for the production and sales of the Atmos, managed by Reutter. In september 1932 LeCoultre made a deal with CGR for the supply of movements, mid 1933 the so called 30″ A calibers were delivered. On July 27 1935 LeCoultre took over the whole production. Another interesting fact is that LeCoultre, after taking over in 1935, kept producing the Atmos I but at the same time was busy with the development of Atmos II. Biggest change was the replacement of the ammonia and lead ´bellows´ with an ethyl chloride canister.

The Jaeger-LeCoultre Atmos clock continues to be a fantastic phenomenon that is rightly given to all the important guests that visit Switzerland.

As a conclusion we can say that Cornelis Drebbel is one of the most gifted persons in Dutch history. Everyone of his inventions are brilliant in itself but it is hard to imagine that the whole list comes from one man. Luckily recently remnants of his house have been found in Alkmaar so that we still have a tangible piece of Cornelis Drebbel left.

Jaap Bakker